- Home

- About Us

- Our Products

- Industry We Serve

- Quality

- Gallery

- Contact us

Get Your Free Quote…!

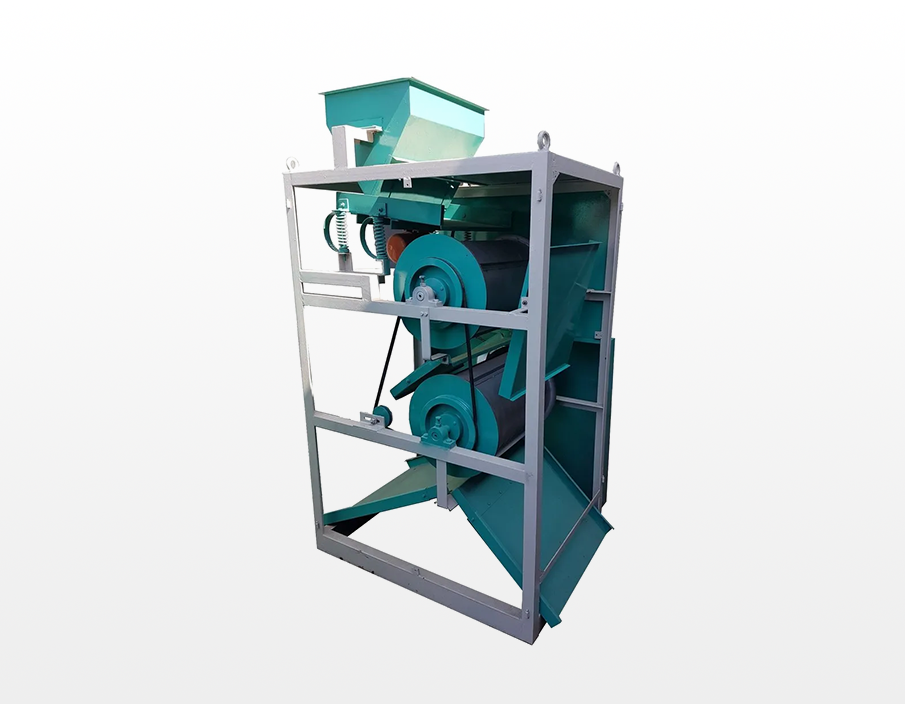

The Double Drum Type Magnetic Separators are highly efficient in achieving the highest purity levels. With its unique design, the material passes through the magnet twice, ensuring effective separation of iron contamination from various products such as minerals, chemicals, and refractory materials. These separators are equipped with a high power permanent magnetic plate at the material outlet, utilizing modern anisotropic permanent magnets that possess exceptional coercivity and long-lasting magnetic strength.

To enhance convenience and minimize dusting and pollution, the machines are designed with a vibrating material inlet hopper and a fully enclosed structure. Additionally, online fitting design options are available to cater to specific requirements. Whether you need to purify minerals, chemicals, or other products, the Double Drum Type Magnetic Separators offer reliable and efficient iron contamination separation, ensuring the highest quality output.

Inquiry| Model No. | No. of Drums | Capacity (Tons / Hour) | Drum Size (mm) | |

|---|---|---|---|---|

| Dia | Length | |||

| SVM-101-SDS | 1 | 1.0 | 300 | 450 |

| SVM-101-DDS | 2 | 1.0 | 300 | 450 |

| SVM-102-SDS | 1 | 1.5 | 400 | 500 |

| SVM-102-DDS | 2 | 1.5 | 400 | 500 |

| SVM-103-SDS | 1 | 2.0 | 400 | 600 |

| SVM-103-DDS | 2 | 2.0 | 400 | 600 |

| SVM-104-SDS | 1 | 3.0 | 400 | 750 |

| SVM-105-DDS | 2 | 3.0 | 400 | 750 |

| SVM-106-SDS | 1 | 5.0 | 450 | 850 |

| SVM-106-DDS | 2 | 5.0 | 450 | 850 |

The magnetic separator with high intensity Rare Earth Nd-Fe-B (Neodymium- Iron- Boron) magnets are useful for removing magnetic contamination with low magnetic properties and fine iron particles are to be separated. The average magnetic intensity on the drum surface will be 3500 – 5500 Gauss.