- Home

- About Us

- Our Products

- Industry We Serve

- Quality

- Gallery

- Contact us

Get Your Free Quote…!

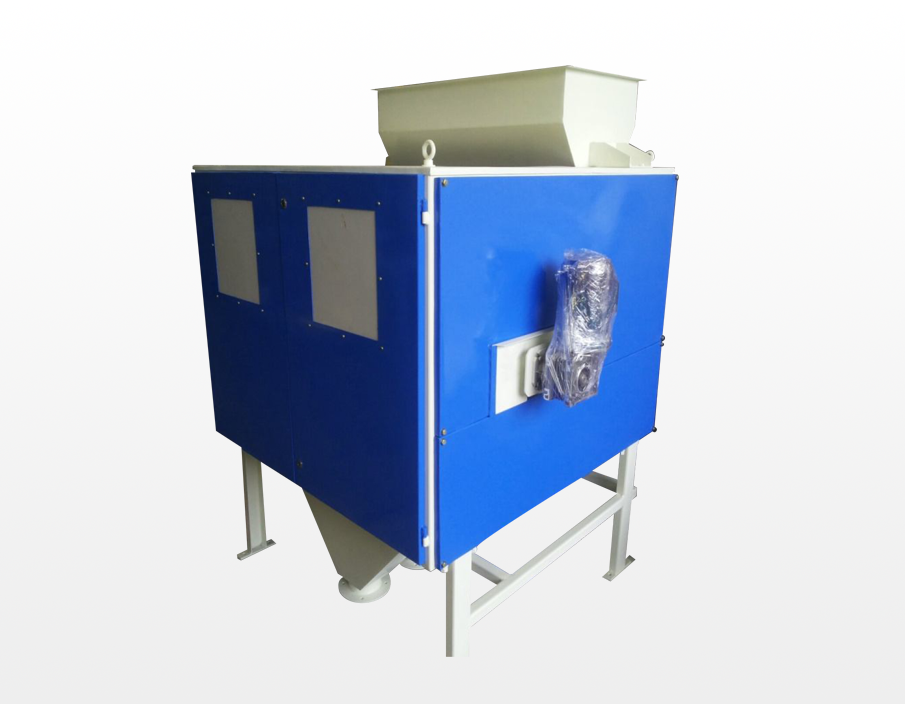

Magnetic Destoner is a highly efficient and reliable machine designed to remove magnetic and non-magnetic impurities from various grains and seeds. With its powerful magnetic field, it effectively separates unwanted materials such as stones, metal fragments, and other contaminants, ensuring the purity and quality of the final product.

This destoner is specifically engineered for industrial applications, offering a high processing capacity and exceptional performance. Its robust construction and durable components make it suitable for continuous operation in demanding environments. The machine is equipped with adjustable settings, allowing for precise control over the separation process to meet specific requirements.

Magnetic Destoner is not only easy to operate but also requires minimal maintenance, reducing downtime and maximizing productivity. Its compact design and user-friendly interface make it suitable for integration into existing production lines. Whether used in the food processing industry or other agricultural applications, this destoner is a reliable solution for achieving superior product purity and enhancing overall efficiency.

InquirySeprion Magnets is a global frontrunner in producing custom Magnetic Destoners using advanced indigenous technology tailored to meet various needs in local and international markets. Our materials and products are ISO 9001 certified, demonstrating the dependability and excellence of our offerings. Magnetic Destoners are primarily utilized for eliminating foreign contaminants from your production lines. Substances such as stones, metals, glass fragments, clumps of mud, black stones, rodent droppings, and other impurities with inherent magnetic characteristics are effectively segregated through the integration of magnetization and density separation.

These Magnetic Destoners are highly efficient, powerful, and long-lasting machines that are utilized for a wide range of separation applications. They are commonly used for separating coffee, beans, seeds, wheat, cereal, maize, rice, soya bean, sunflower seed, legume, barley, oat, malt, nut, millet, kamut, green lentils, black jasmine rice, quinoa, barley groats, buckwheat groats, sushi rice, basmati rice, corn kernels, couscous, pearled couscous, cowpea, green peas, red lentils, mung bean, chickpeas, puy lentils, green split peas, aduki beans, dalia, mixed beans, black eyed peas, iodized salt, kidney beans, yellow split peas, Flageolet beans, pinto beans, marrow fat beans, black turtle beans, and many other materials.

Our high quality magnetic destoner is capable of separating impurities from a variety of spices such as red chillies, kebab masala, tikka masala, mild madras curry, ginger, turmeric, red colouring food, garlic, coriander seasoning, lamb seasoning mix, black pepper, red paprika, saffron, sage, rosemary, parsley, thyme, cumin, and many more.

The Magnetic Destoner separator operates based on a specific working principle. It consists of a magnetic roll and a tensioning ideal roll, which are enclosed by a short conveyor belt. Materials are discharged onto the belt through a suitable feeder. As the belt moves, the ferromagnetic and paramagnetic particles stick to it, while the nonmagnetic particles are able to flow off freely at the end of the conveyor.

Our Magnetic Destoner machines find applications in a wide range of industries, including mineral processing for materials like abrasive, refractory, and ceramic raw materials such as alumina, silica, carbide, magnesite, and quartzite. They are also utilized for cleaning glass raw materials like silica, quartz, feldspar, and dolomite. Additionally, these machines are employed for ultra-high purity quartz cleaning, graphite upgrading, manganese ore beneficiation, bauxite upgrading, diamond ore beneficiation, selective separation of garnet/ilmenite/rutile, zircon, iron ore beneficiation, recovery of metals from slag, removal of ferrous silicates from limestone, magnesite, and more. Moreover, our magnetic destoners are essential in food processing industries for removing mud balls from wheat, rice, sesame, semolina, cumin, fennel, chilly flakes, and various other food products.

Our testing facilities include live demonstrations of machine operations at our facility. We offer free testing of small samples weighing approximately 5-20 Kgs. to showcase the performance of our machines.